Choosing between a 6-point or 12-point socket can significantly impact your repair or assembly efficiency. In this guide, we break down the real-world differences between the two socket types—how they grip hex nuts, handle torque, and help prevent wear. Whether you’re a seasoned technician or just building your tool kit, this comparison will help you make the right choice.

Do I need a 6-point socket setor a12-point socket set?

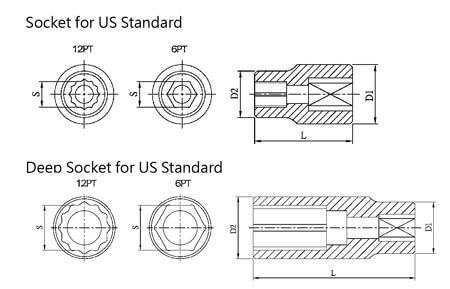

A hex nut has 6 points. Both6-point and 12-point sockets can be fitted on hex nuts, the primary differences being convenience and torque. The more points a socket has, the more points of contact available. Compared with the 6-point socket, a 12-point socket has twice as many points, so it can more easily slide onto a hex nut. In other words, you would need to rotate only up to 30 degrees to fit a 12-point socket onto a hex nut. This can prove to be a time-saver and make life easier when you’re working within confined spaces.

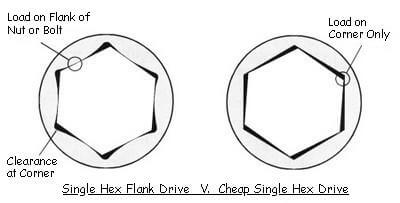

On the other hand, 6-point sockets help reduce wear on the nut corners, and they also have better torque performance than 12-point sockets, for two reasons:

1) As the flanks of a 6-point socket are thicker than those of a 12-point socket, torque can be evenly applied on each side of the hex nut.

2.) Torque power load is borne by the flanks of the nut or bolt instead of by the corners.

However, you must use a 12-point socket with a 12-point fastener (such as the old Camry internal bolts).

In conclusion, every professional craftsman should own a complete set of 6-point sockets. While a 12-point socket set isn’t absolutely necessary, it is nice to havel.

Fun Fact

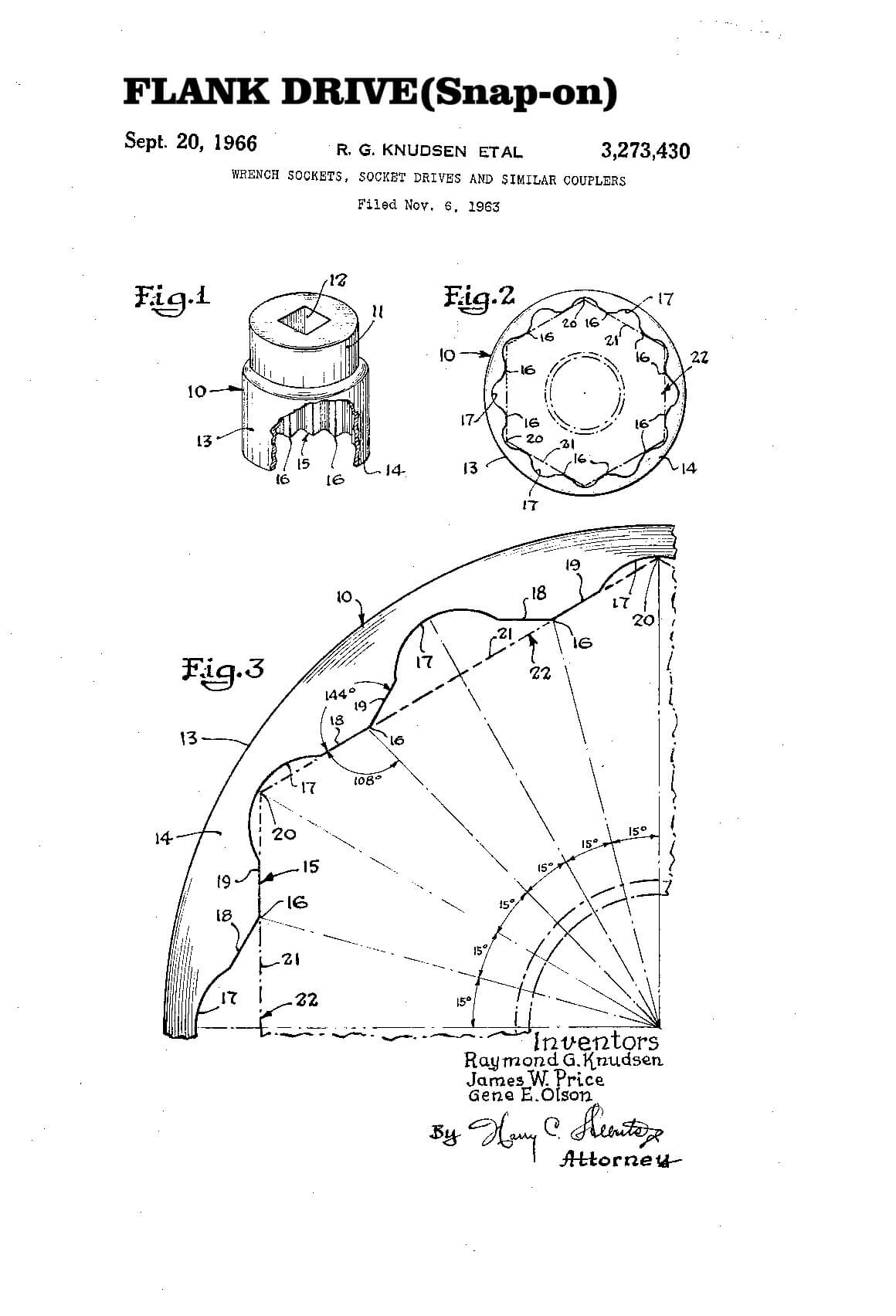

In 1996, Snap-On patented its 12-point flank drive, designed to reduce wear on hex nuts or bolts. To this day, this invention remains one of the most popular socket patents applicationsin the world.

Kingsdun is a precision screwdriver manufacturer, if you are looking for a Chinese screwdriver manufacturer, please contact us, we will give you the most sincere advice, thank you